| a) Cutting |

| Shearing: Straight-line cutting using guillotine shears. |

| Laser Cutting: High-precision cutting with CNC-controlled lasers (CO₂ or fiber). |

| Plasma Cutting: For thick metals using ionized gas jets. |

| Waterjet Cutting: Uses high-pressure water (with abrasives for hard metals). |

| Punching/CNC Turret Punching: Creates holes or cutouts using dies. |

| b) Bending |

| Press Brake Bending: Uses a punch and die to form V-bends, U-bends, etc. |

| Roll Bending: For curved parts (e.g., cylinders). |

| Folding: Specialized machines create complex bends. |

| c) Forming |

| Stamping: High-volume production using dies (e.g., automotive panels). |

| Deep Drawing: Forms sheet metal into hollow shapes (e.g., cans, enclosures). |

| Hydroforming: Uses fluid pressure to shape metal. |

| Spinning: Rotates metal on a lathe to form axisymmetric parts. |

| d) Joining |

| Welding : MIG, TIG, spot welding for permanent joints. |

| Riveting : Mechanical fastening with rivets. |

| Adhesive Bonding : Uses industrial adhesives. |

| Clinching : Interlocking sheets without fasteners. |

| e) Finishing |

| 2. Common Materials Used |

| Mild Steel (low-cost, weldable) |

| Stainless Steel (corrosion-resistant) |

| Aluminum (lightweight, good for bending) |

| Copper/Brass (electrical/decoration applications) |

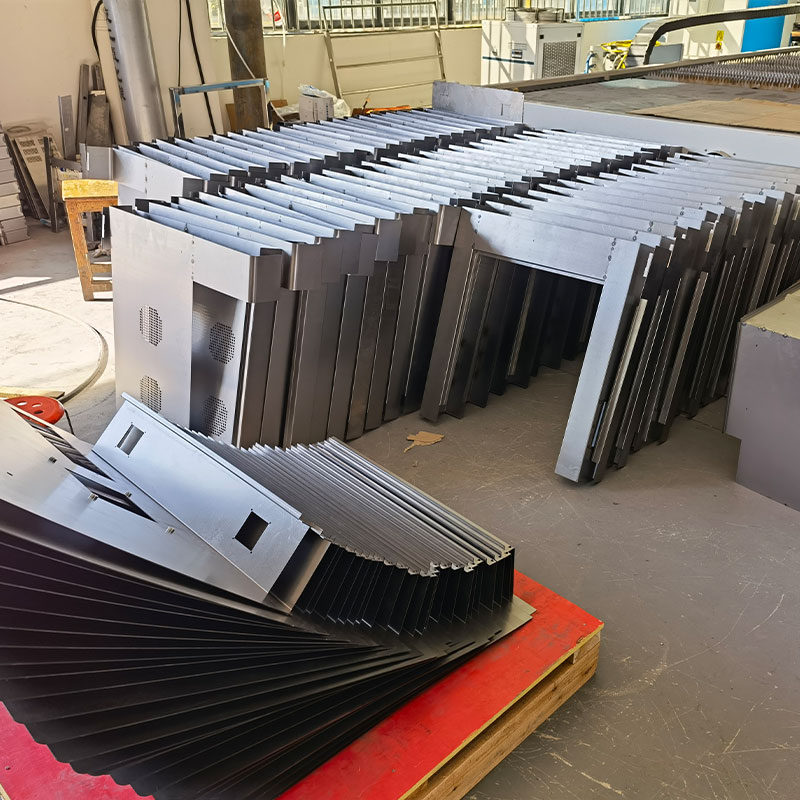

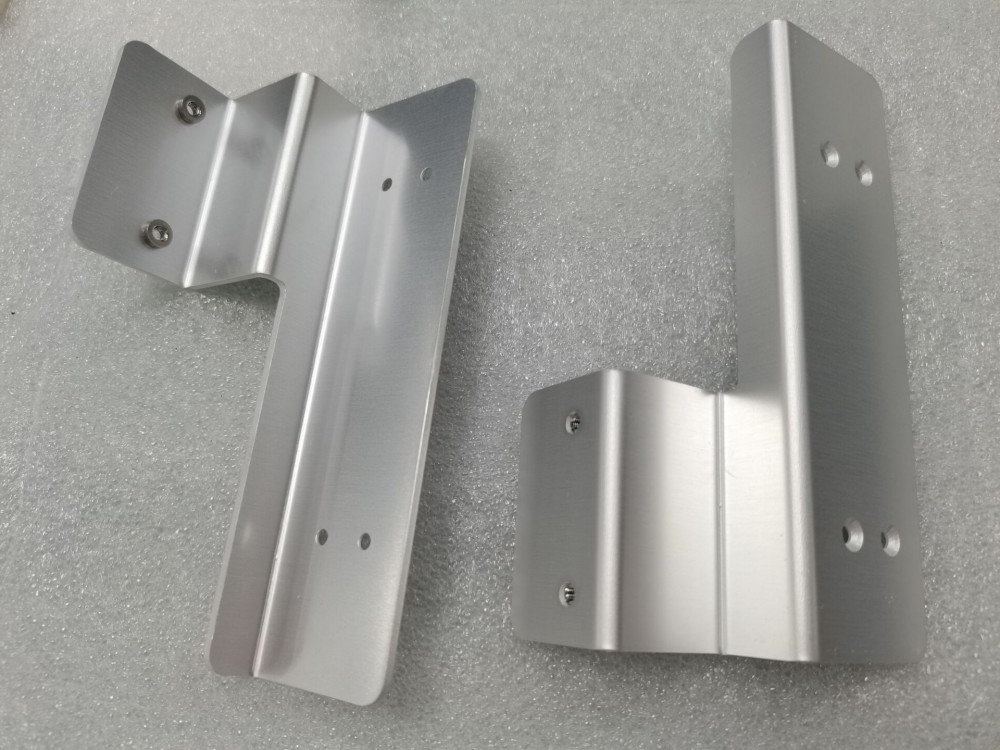

| 3,Metal Sheet shop and part of products display |